Symptoms of a Failing Transfer Case

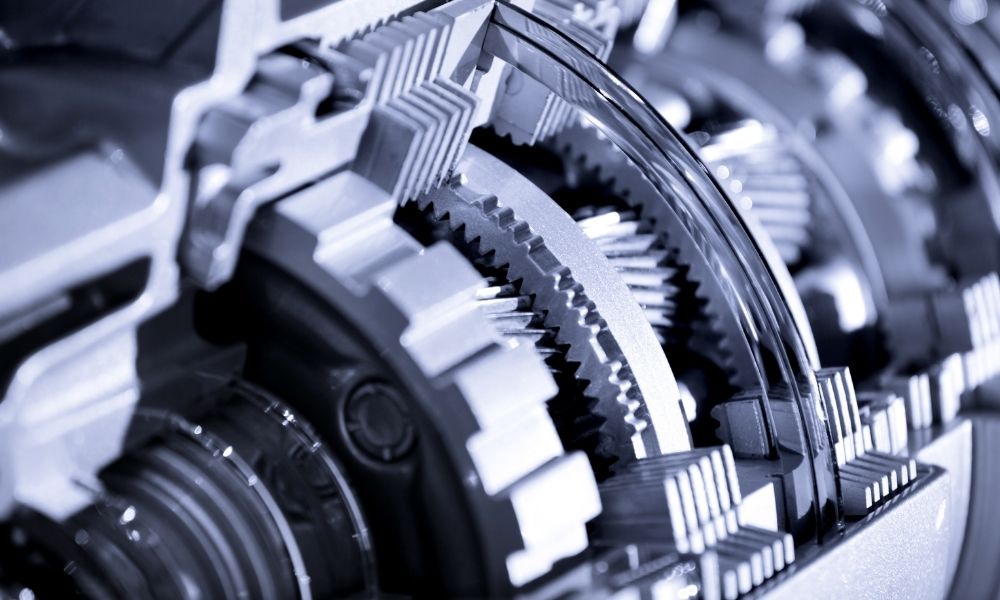

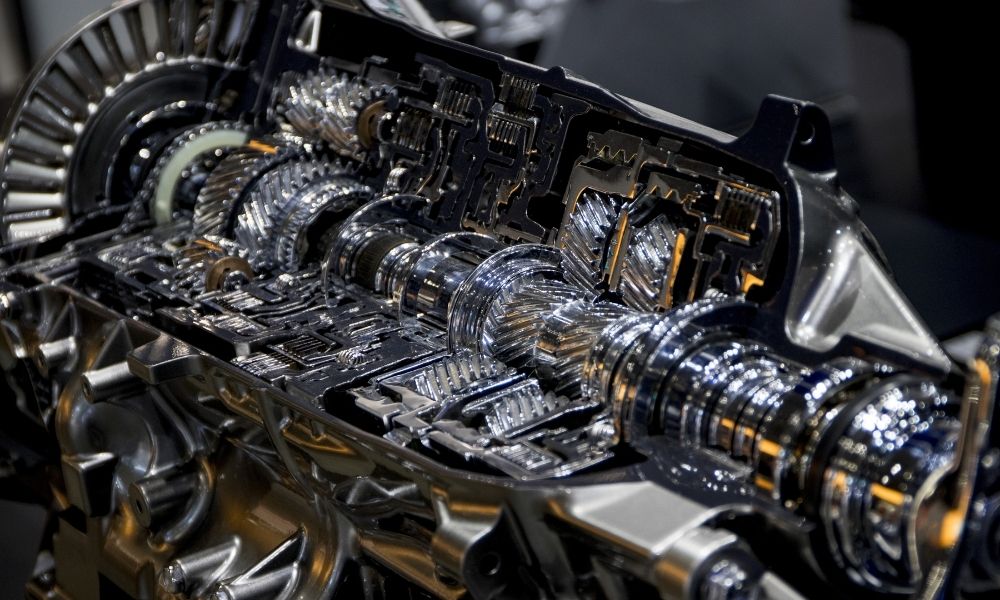

A transfer case is an important part of a vehicle’s drivetrain. If a transfer case malfunctions, a multiple powered axle vehicle—such as a four-wheel-drive or all-wheel-drive vehicle—would not be able to transfer power from the transmission to the front and rear axles. As a result, the vehicle’s four-wheel or all-wheel drive operations would fail to work properly. In addition, a faulty transfer case could also cause damage to other vehicle components, such as the transmission. To ensure you can address any issues before additional vehicle damage occurs, take a look at these symptoms of a failing transfer case.

Trouble Shifting Gears

Problems shifting gears is a common sign of a malfunctioning transfer case. The transfer case and transmission both rely on the output shaft seal to prevent fluid from leaking out. If this seal breaks, a loss of fluid and pressure will occur within the transmission, which can make it difficult to switch gears properly. If you have problems shifting into higher or lower gears, get your vehicle checked for an internal transfer case failure.

Popping In and Out of 4WD

Another indication that your vehicle may have a transfer case failure is if it pops in and out of four-wheel-drive. When a vehicle jumps in and out of four-wheel-drive, it is often due to a loss of fluid. Such fluid loss can cause the components inside the transfer case to wear out and break prematurely, which will prevent the vehicle from staying in or out of four-wheel-drive as it is supposed to.

Pooling Fluid Under Transfer Case

If reddish fluid begins to pool directly under the transfer case, there is most likely a problem with the transfer case itself, such as a broken seal or gasket. To determine if a leak is coming from your transfer case, jack up your car and inspect it visually. In most models, the transfer case is located at the rear end of the transmission or transaxle assembly. If you notice a leak, make sure to addr